What factors affect coffee quality during storage?

Understanding and analyzing the deterioration of coffees: in this article, you'll find out which factors affect coffee quality.

Deterioration in the quality of green coffee during storage is a reality. It manifests itself in bleaching of the green beans and loss of the beverage's organoleptic qualities.

We have observed that degradation times vary greatly depending on the initial quality of the coffees. The Belco quality protocol makes it possible to explore and analyze the various parameters linked to these degradations. We carried out a statistical correlation analysis on over 4000 references and 3 harvest years.

This showed that humidity and water activity (Aw) are the most correlated and influential physical parameters on taste variation between coffee departure and arrival in the storage port.

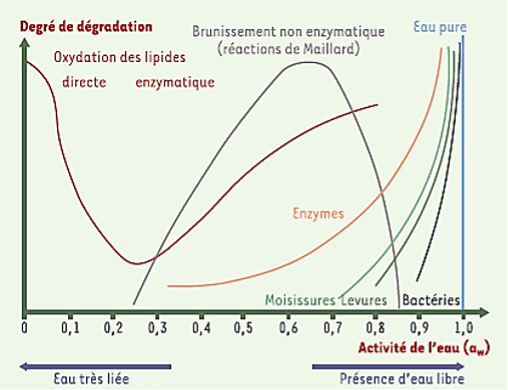

The standard moisture and water activity levels recommended by the ICO are: 8 to 12.5% and 0.5 to 0.7 Aw. These limits are set for sanitary reasons, to prevent the proliferation of fungi, moulds and toxins such as ochratoxin A.

Definitions

- Moisture: percentage of water in total mass. It is the quantity of water.

- Water activity (Aw): Quantity of water available to undergo interactions with coffee and external elements (molds, enzymes, yeasts).

Belco analysis

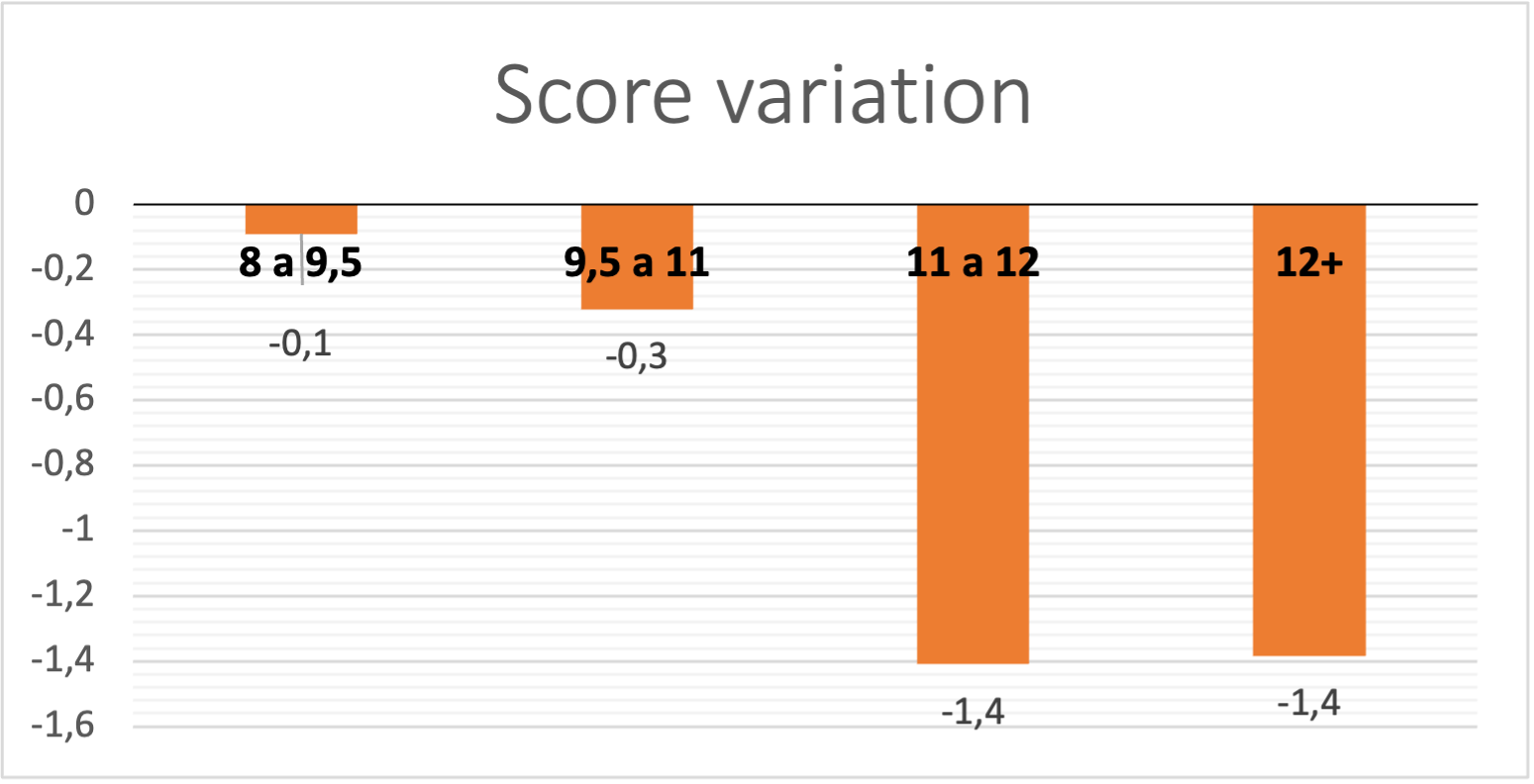

When humidity and Aw parameters are high, coffee loses an average of 1.4 points between pre-boarding tasting and arrival. The difference is all the more significant on higher-quality coffees, where the "baggy" and "paper" taste notes cause the coffee to lose up to 6 points (SCA score).

Figure 1: Variation in score between embarkation and arrival as a function of humidity. Average carried out on all coffees analyzed since 2018. Over 4000 references and 2 harvests.

The graph shows a significant difference in the variation of scores with different humidities. This is due to the proliferation of exogenous agents on the coffee bean. Molds and yeasts do not develop below 12.5% and 0.7 Aw. However, these high parameters are conducive to the presence of enzymatic activity.

Figure 2: Food spoilage and proliferation of exogenous agents as a function of Aw.

Certain enzymes, such as pectinases, can therefore develop on the bean and cause considerable loss of flavor. Pectinase enzymes attack pectin, the main component of the cell wall in coffee beans. Once the pectin has been degraded, the cells are no longer protected from external conditions, leading to the death of the embryo.

The results of this research have enabled Belco to define new internal specifications. The requirements for these parameters have been raised from 12.5 to 11% maximum humidity, and to 0.65 for water activity. Belco is keen to support producers from the Quality department and through field engineers to identify the ideal drying techniques adapted to the conditions of each drying station.

We have also equipped our field teams with portable hygrometers to measure humidity throughout the drying, storage and transport process, which, in addition to preventing the presence of toxins, will minimize coffee spoilage, reduce our complaints to producers and improve the quality of coffees supplied to our customers.

Jean Etchats, Belco Quality manager

Did you like this article? Share it with your community: