Quality, our focus for your coffee.

Quality plays a big part in our ongoing quest to innovate and promote local terroirs, an effective development tool for producers. Our team supports you every step of the way along the coffee chain. Discover our quality protocol.

More than just quality control

We place a focus on continuous improvement and are in permanent contact with our partner producers. As a result, we have a better understanding of each step in the quality chain, from bean genetics and sorting to agroforestry and roasting, all fundamental to ensuring you enjoy a quality product.

The Quality Crew

10 people: agronomists, Q Graders, roasters and baristas

Our labs

Working in 4 identical laboratories in France, Ethiopia, Colombia and El Salvador. To give you an idea, each year, we cup 3,000 samples in France to select the 500 coffees featured in our catalog. Our lab in France is certified CQI (Coffee Quality Institute)

At every step of your coffee

Coordinated action throughout the coffee value chain, with a focus on quality

Our state-of-the-art warehouse in Le Havre

10% of each container or pallet (for sail shipments) is inspected — not just a random bag!

Smell, color, stones, twigs — thanks to our representative samples, nothing is overlooked.

A fully digitalized protocole

via our app, Le Lab, to ensure the most reliable data quality possible, accessible in real time by roasters.

Analysis at every stage

Each of your coffees is analyzed five times, from the start of the harvest all the way to its delivery at your warehouses.

Farm Samples

We take samples before sorting to create lots, prepare contracts and make sorting recommendations

Offer Samples

We create an offer, to introduce new coffees

Pre-Shipment Samples

We prepare samples representative of the final lot, for coffee import approval

Arrival Samples

We analyze coffee samples on their arrival at port, before market release

Stock Control

We carry out quality controls on coffees stored in our warehouses for more than 6 months

Our analysis criteria

We analyze coffee beans at each stage to ensure there are no major defects, prevent external contamination, and guarantee stability over time.

Moisture & density

Moisture content is a measurement of the water present in a green coffee bean. It is expressed as a percentage of total weight. The International Coffee Organization sets bean moisture content standards at between 8% and 12.5%, but Belco sets a limit of 11.5% to ensure better conservation. We assist producers with their drying processes to make this possible.

Water is the main conductor of heat, so a bean’s moisture content also affects roasting. It plays a role in determining the amount of energy needed to trigger the chemical reactions.

Density is a measurement of the weight of a coffee bean proportional to its volume, expressed in g/L. The density of a coffee typically falls between 650 and 800 g/L.

How does density affect roasting? The denser the coffee, the more resistant it is, so the more difficult conduction becomes.

Water activity

Water activity is a common indicator used in food preservation. It is a measurement of the energy of the water and its distribution within a bean. Water in a bean that has been dried correctly is distributed evenly, promising better bean preservation. Water activity ranges from 0.45 to 0.65 Aw.

In terms of roasting, water activity is an important consideration for managing stocks of green coffee and will have an effect on the roasting profile over time.

UV radiation

UV light highlights some fluorescence invisible to the human eye. Fluorescent beans are generally broken beans, with a high water activity and lipid content. UV radiation is a useful decision-making tool, combined with the other lab analyses.

Screen

Screens are used to measure the size of a green coffee bean. At Belco, we use mechanical sieves ranging from 12 to 18 in size. For a coffee to be officially considered a 16+, for example, 90% of the weight of the beans must be situated on a 16 sieve or above. Some countries go by different rules, such as Kenya, where “AA” is equivalent to an 18+ screen.

Screens play an important part in roasting. A more even screen distribution gives roasters more control.

Defect count

At Belco, we use the SCA counting model. We also compile specifications for each coffee and each country. Defects are defined by official bodies. Each country has its own definitions, equivalences and rules.

Some defects affect roasting, others will influence the cup, while some have no impact at all, either during roasting or cupping.

Colorimetry

Colorimetry is used to measure bean colour. We can analyze this data to evaluate bean conformity between two samples and possible changes in colour.

It can be an indicator of how rapidly the colour will change when roasting.

Sample roasts

Our quality team roasts all our samples following a precise roasting protocol. Our aim is to unlock a coffee’s full potential in a “medium” roast. We can use this process to assess each coffee’s aromatic profile and assign an SCA score.

Cupping

The tasting method used worldwide to analyze a coffee is known as “cupping”. It follows a strict protocol that controls coffee grind parameters, water temperature and quality, the water/coffee ratio and the infusion time. We evaluate 10 cupping attributes to give the coffee a qualitative score out of 100 and determine its aromatic profile.

We have a panel of Belco tasters that includes at least one Q Grader. They taste each coffee in 5 cups in accordance with the SCA protocol.

Beyond organic

Every year since 2018, Belco has increased the volume share of organic coffees made available to customers by 15%. More than just a trend, organic farming is a sustainable means of production that addresses today’s environmental concerns.

We analyze all our organic coffees in search of pesticide residues, to provide products in line with our vision of organic farming. Belco is committed to stocking products that meet its own specifications, which are even more stringent than European standards.

Support & training for producers at origin

A genuine connection, from the ground up

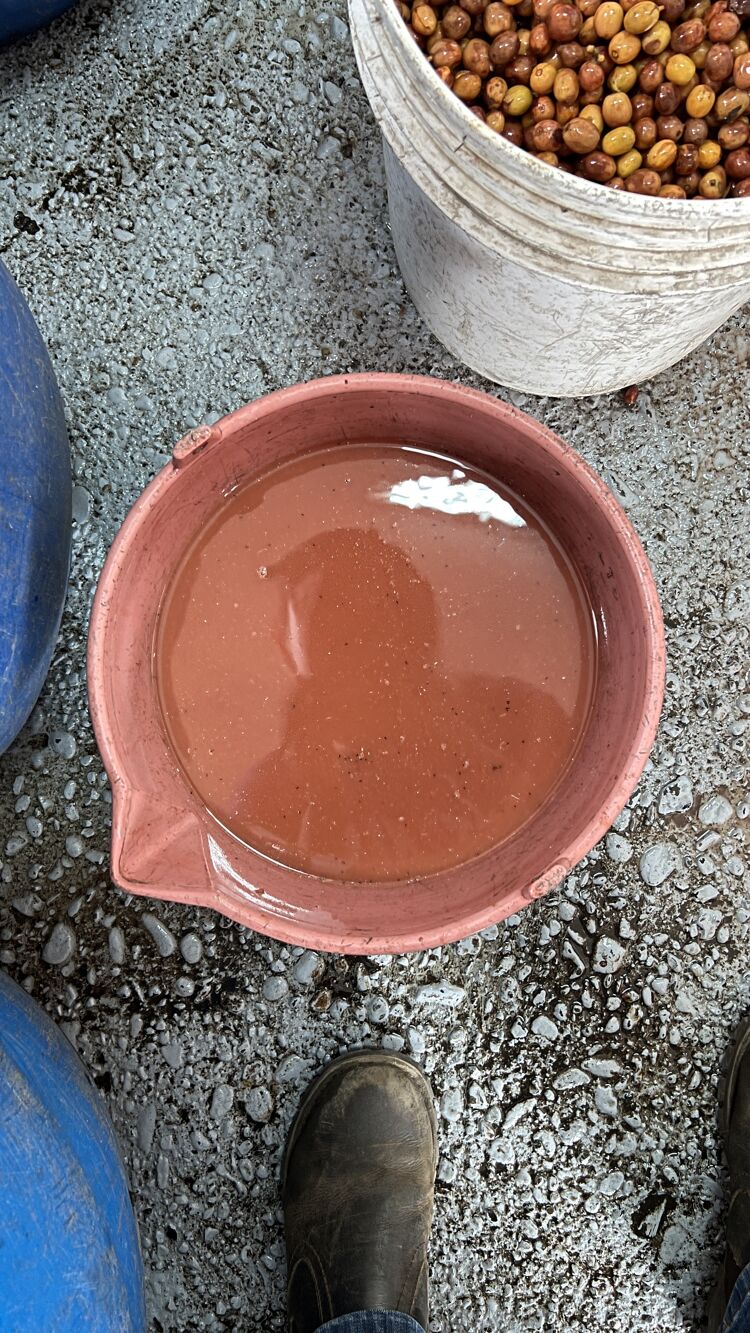

Our quality team works hand in hand with producers to guarantee and improve quality, including after picking, to help create lots and to research and innovate different processes, with a particular focus on sorting.

Our teams on the ground provide year-round training for producers on the different quality approaches used in our industry.

They hold workshops for farmers at various stages of harvesting and through to cupping, to help them unlock the full potential of their coffees.

Focus on post-harvest processes

We work with producers to explore new organoleptic profiles, to create new coffees using innovative drying and fermentation techniques.

Producer kits

Training in bean analysis

We offer producers a kit containing scientific toolsand a guide, to encourage them to improve qualityvia good processing techniques, giving them the opportunity to control and understand their coffees better.With the right tools, it becomes easier to improve qualityand consistency. The kit includes a moisture meter, thermometer, refractometer and pH tester.

Roasting analysis, at your service

Our quality team is on hand to address all your roasting needs. Our laboratory at Mérignac is fully equipped to analyze roast quality. You will be welcomed by our roaster, Denis, manager of our School of Coffee and a recently qualified Q Grader. He offers a range of customizable training courses.

More about our commitments

How we source your coffees

Active, customized sourcing on the ground.

Supply

Transport by sail, warehouses... it’s all here!